- (03) 5909 8218

- enquiry@fusionweld.com.au

Shell & Tube Heat Exchangers: Improve Thermal Control & Energy Recovery in Petrochemical & Pharmaceutical Plants

September 09, 2025

Maintain compliance with Fusion-Weld Engineering, Australia’s trusted provider of shell and tube heat exchanger inspection and certification services.

Shell and tube heat exchangers are vital in process industries where temperature consistency and energy efficiency impact both performance and cost. These thermal transfer units are relied upon to manage heat flow, conserve energy, and sustain operational safety. In high-demand sectors like petrochemical and pharmaceutical manufacturing, shell and tube heat exchangers support stable thermal control while promoting responsible energy use.

Understanding Shell and Tube Heat Exchangers

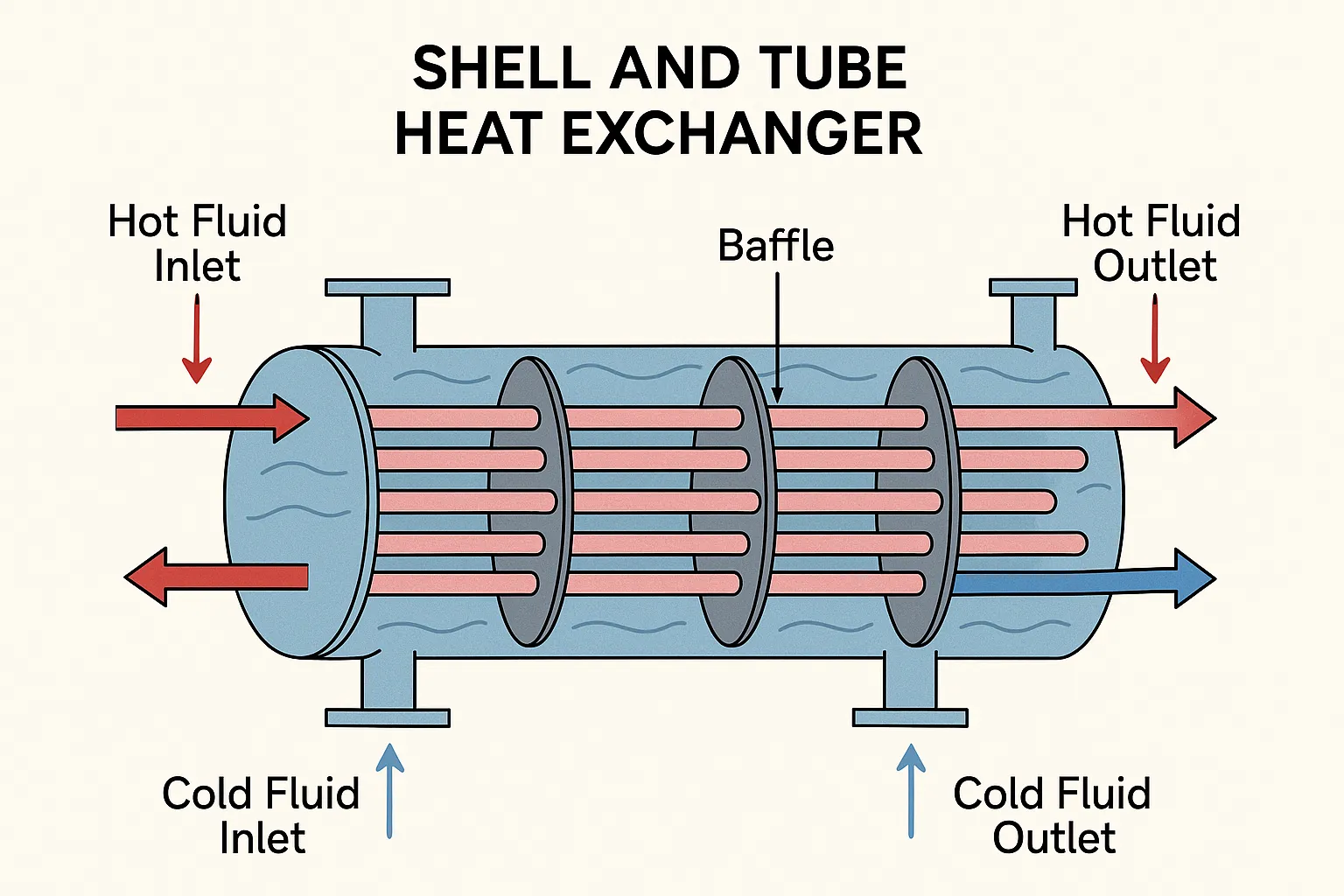

Shell and tube heat exchangers are pressure-retaining devices designed to transfer heat between two fluids. Their structure features a cylindrical outer shell containing multiple tubes. Fluids flow through and around these tubes, guided by tube sheets and supported by baffles to maximise surface area and heat transfer. This configuration is well-suited for demanding conditions involving elevated temperatures and pressures, making shell and tube heat exchangers a trusted solution in industrial environments.

Thermal Control Benefits in Petrochemical Plants

Precise thermal regulation is essential in petrochemical plants, as efficiency and product quality depend on stable operating conditions. Shell and tube systems offer a reliable solution for managing heat under pressure, ensuring consistent temperature control across varied applications.

Their proven durability allows them to withstand harsh chemicals and extreme thermal loads, making them well-suited for complex operations. From heat recovery in fractionation columns to feedstock pre-heating and reactor integration, these systems deliver dependable performance and long-term reliability.

Energy Recovery in Pharmaceutical Manufacturing

Pharmaceutical manufacturing relies on efficient thermal management, and the tube bundle heat exchangers enable effective energy recovery throughout critical processes. By reusing thermal output for solvent heating, CIP loops, and fermentation cooling, these systems lower energy consumption and reduce emissions. This improves cost-efficiency, supports environmental compliance, and maintains strict hygiene and safety standards.

The white paper Materials Selection Issues for Heat Exchangers in the Pharmaceutical Industry highlights the importance of choosing materials such as 316L stainless steel and resin-impregnated graphite to ensure durability, hygiene, and compatibility with sensitive pharmaceutical processes. This strategic material selection directly supports the efficient and sustainable performance of shell-and-tube heat exchangers, helping to lower energy consumption, reduce emissions, and maintain compliance with stringent industry standards.

Design Flexibility and Maintenance Advantages

Shell and tube systems offer easy access for cleaning and inspection, ensuring strict hygiene in pharmaceutical production and supporting routine servicing in petrochemical plants. To meet diverse industrial requirements, these systems can be customised with design features that enhance performance and efficiency:

• Custom Tube Layouts - Enable non-standard flow paths to optimise heat transfer for specialised processes.

• Material Options - Allow selection of alloys or sterile-grade materials to handle corrosive or hygienic fluids.

• Removable Tube Bundles - Simplify cleaning, inspection, and maintenance to minimise downtime.

• Baffle Spacing - Can be adjusted to manage variable pressure drops and enhance thermal performance.

• Compact Sizing - Provides efficient heat exchange in space-limited plant areas without sacrificing capacity.

Fusion-Weld Engineering: Experts in Shell and Tube Heat Exchanger Inspection

Fusion-Weld Engineering provides independent, experienced, and ethical periodic in-service inspection and certification services for pressure equipment. We conduct detailed inspections of shell and tube heat exchangers to ensure ongoing reliability, performance, and regulatory compliance.

For expert evaluation or re-certification of your pressure equipment, contact us at Fusion-Weld Engineering to schedule your next inspection.

Related Blog Article: Heat Exchangers for Oil & Gas Refineries - Custom-Built for Performance & Compliance

Contact Details

Fusion - Weld Engineering Pty Ltd

ABN 98 068 987619

1865 Frankston Flinders Road,

Hastings, VIC 3915

Ph: (03) 5909 8218

Optimized by NetwizardSEO.com.au

Recent Posts

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- Pressure Vessel Fabrication: Engineering Efficiency for 2026 Petrochemical Projects

- Heat Exchanger Maintenance in Melbourne: Minimising Risk in Power Generation Facilities

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- AS1210 vs ASME VIII Pressure Vessel Code: Key Differences for Australian Projects

- Mitigating Hydrogen-Induced Cracking in Pressure Vessels: Engineering and Material Strategies

- Storage Tank Solutions Australia: Field-Erected, Prefabricated & Self-Bunded Explained

- Reducing Environmental Risks: Self-Bunded Tanks in Australian Oil & Gas Operations

- Precision in Production: How Pressure Vessels Are Manufactured for Industrial Safety

- Shell & Tube Heat Exchangers: Improve Thermal Control & Energy Recovery in Petrochemical & Pharmaceutical Plants

Posts 2026

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- Pressure Vessel Fabrication: Engineering Efficiency for 2026 Petrochemical Projects

- View all articles…

Posts 2025

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- View all articles…

Posts 2024

- Large Process Vessels: Optimising the Design for Maximum Efficiency [2025]

- Pressure Equipment Management System Installation: Detect Equipment Faults Early

- View all articles…

Posts 2023

- Pressure Piping System Inspection: A Gift of Safety for the Holidays

- Deaerator Inspections by Fusion-Weld Engineering and How They Reduce System Downtime

- View all articles…

Posts 2022

- How Fusion Weld Keeps Up With AS-NZS ISO 9001:2008 Standard

- Boiler Equipment Safety Inspection During the Summer Season

- View all articles…

Posts 2021

- Avoid These Factors and Practices that Contribute to Sealing Damage in Pressure Vessels

- Do's And Don'ts Of Industrial Boiler Inspection And Maintenance From Fusion-Weld

- View all articles…

Posts 2020

- What are the Risks and Hazards Involved in Pressure Vessel Equipment?

- How to Know if Your Pressure Equipment Needs Repair or Replacement?

- View all articles…

Posts 2019

- Factors that Contribute to Pressure Vessel Failure

- Pressure Vessel Regulations in Australia: What are the Mandatory Requirements?

- View all articles…

Posts 2018

- Pros and Cons of Spherical vs. Cylindrical Pressure Vessels

- What are the Different Hazard Levels in Pressure Vessels?

- View all articles…

Posts 2017

- Transportable Pressure Vessels: The Importance of Inspection and Safety Checks

- Fracture Mechanics and Stress Analysis of Cracks in Pressure Vessels

- View all articles…

Posts 2016

Posts 2015

- What Are Deaerators & Feedwater Vessels?

- Precautions and Safety for Compressed Air Receiver Vessels

- View all articles…

Posts 2014

- Demonstrating In-process Inspection Procedures

- Static Grounding Practices and Standards

- View all articles…