- (03) 5909 8218

- enquiry@fusionweld.com.au

Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

February 18, 2026

Plan modular plant delivery in 2026 with process skid fabrication in Melbourne by Fusion-Weld Engineering for an engineered and compliant skid-mounted system.

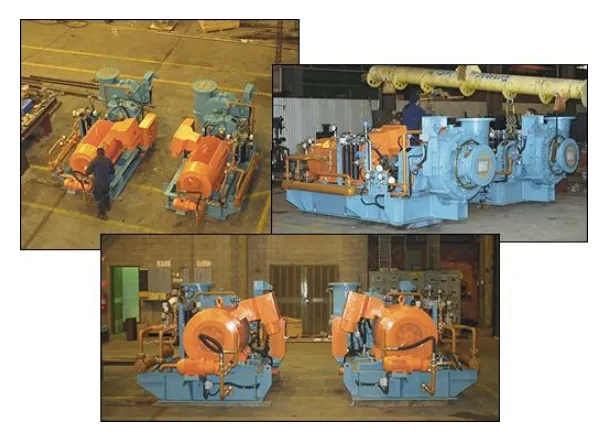

Industrial developments planned for 2026 demand fabrication strategies that improve certainty, safety, and construction efficiency. Process skid fabrication in Melbourne continues to support these requirements through modular systems manufactured under controlled workshop conditions. Prefabricated skids allow complex process equipment to be delivered as complete, install-ready assemblies.

Process Skid Fabrication Melbourne for Modular Plant Delivery

Process skid systems are engineered assemblies that integrate piping, vessels, pumps, and structural steel into a single transportable framework. This fabrication approach enables detailed quality control, dimensional accuracy, and functional testing before the equipment reaches the site.

For capital projects operating under strict timelines, process skid fabrication in Melbourne supports off-site construction strategies that reduce site labour exposure and improve coordination. Modular delivery also simplifies installation sequencing and minimises disruption to live operating environments.

Industrial Drivers for Modular Skid Systems in 2026

Future-facing industrial projects prioritise modular plant construction to manage workforce availability and compliance oversight. Process skid fabrication in Melbourne supports these objectives by shifting complex fabrication activities into certified workshops.

This approach enhances traceability, simplifies inspection processes, and improves overall build consistency. Projects governed by Australian Standards benefit from documented fabrication records and reduced site-based risk.

Operational Applications of Modular Skid Systems

Modular skid systems support a wide range of industrial process requirements across diverse sectors. These assemblies are engineered to achieve consistent operational performance, robust safety integration, and long-term maintainability in demanding industrial environments.

• Chemical Processing Facilities: Skids integrate piping, valves, and vessels designed to safely manage corrosive or hazardous media.

• Water and Wastewater Treatment Plants: Modular skids streamline filtration, dosing, and pumping systems within compact footprints.

• Energy and Utility Infrastructure: Skid-mounted systems house auxiliary process equipment for power generation and distribution facilities.

• Food and Beverage Manufacturing: Hygienic skid designs support clean-in-place operations and strict sanitation standards.

• Mining and Resource Operations: Transportable skids provide reliable process solutions for remote or temporary installations.

Fabrication Standards and Quality Assurance Controls

Certified welding procedures are applied to ensure weld integrity across structural and pressure-retaining components. Fabrication activities comply with applicable pressure piping and vessel standards to meet regulatory and safety requirements. These controls ensure each skid assembly performs reliably under operational loads and process conditions.

Workshop-based dimensional control improves fit-up accuracy and alignment at all mechanical and piping interfaces. Pre-delivery functional testing verifies system performance, control integration, and operational readiness before site mobilisation. Full material traceability is maintained to support compliance audits, maintenance planning, and long-term asset lifecycle management.

Modular Skid Fabrication for 2026 Industrial Projects

Industrial operators planning upgrades or new facilities benefit from experienced modular fabrication capability. Process skid fabrication in Melbourne enables 2026 projects to achieve predictable delivery, reduced site risk, and improved commissioning efficiency.

Fusion-Weld Engineering delivers engineered skid-mounted solutions designed for demanding industrial environments. Modular plant systems are fabricated, tested, and prepared to meet Australian Standards and project specifications.

For upcoming projects requiring reliable modular fabrication support, contact us.

Related Blog Article: Skid Mounted Systems: Revolutionising Petrochemical Processing

Contact Details

Fusion - Weld Engineering Pty Ltd

ABN 98 068 987619

1865 Frankston Flinders Road,

Hastings, VIC 3915

Ph: (03) 5909 8218

Optimized by NetwizardSEO.com.au

Recent Posts

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- Pressure Vessel Fabrication: Engineering Efficiency for 2026 Petrochemical Projects

- Heat Exchanger Maintenance in Melbourne: Minimising Risk in Power Generation Facilities

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- AS1210 vs ASME VIII Pressure Vessel Code: Key Differences for Australian Projects

- Mitigating Hydrogen-Induced Cracking in Pressure Vessels: Engineering and Material Strategies

- Storage Tank Solutions Australia: Field-Erected, Prefabricated & Self-Bunded Explained

- Reducing Environmental Risks: Self-Bunded Tanks in Australian Oil & Gas Operations

- Precision in Production: How Pressure Vessels Are Manufactured for Industrial Safety

- Shell & Tube Heat Exchangers: Improve Thermal Control & Energy Recovery in Petrochemical & Pharmaceutical Plants

Posts 2026

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- Pressure Vessel Fabrication: Engineering Efficiency for 2026 Petrochemical Projects

- View all articles…

Posts 2025

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- View all articles…

Posts 2024

- Large Process Vessels: Optimising the Design for Maximum Efficiency [2025]

- Pressure Equipment Management System Installation: Detect Equipment Faults Early

- View all articles…

Posts 2023

- Pressure Piping System Inspection: A Gift of Safety for the Holidays

- Deaerator Inspections by Fusion-Weld Engineering and How They Reduce System Downtime

- View all articles…

Posts 2022

- How Fusion Weld Keeps Up With AS-NZS ISO 9001:2008 Standard

- Boiler Equipment Safety Inspection During the Summer Season

- View all articles…

Posts 2021

- Avoid These Factors and Practices that Contribute to Sealing Damage in Pressure Vessels

- Do's And Don'ts Of Industrial Boiler Inspection And Maintenance From Fusion-Weld

- View all articles…

Posts 2020

- What are the Risks and Hazards Involved in Pressure Vessel Equipment?

- How to Know if Your Pressure Equipment Needs Repair or Replacement?

- View all articles…

Posts 2019

- Factors that Contribute to Pressure Vessel Failure

- Pressure Vessel Regulations in Australia: What are the Mandatory Requirements?

- View all articles…

Posts 2018

- Pros and Cons of Spherical vs. Cylindrical Pressure Vessels

- What are the Different Hazard Levels in Pressure Vessels?

- View all articles…

Posts 2017

- Transportable Pressure Vessels: The Importance of Inspection and Safety Checks

- Fracture Mechanics and Stress Analysis of Cracks in Pressure Vessels

- View all articles…

Posts 2016

Posts 2015

- What Are Deaerators & Feedwater Vessels?

- Precautions and Safety for Compressed Air Receiver Vessels

- View all articles…

Posts 2014

- Demonstrating In-process Inspection Procedures

- Static Grounding Practices and Standards

- View all articles…