- (03) 5909 8218

- enquiry@fusionweld.com.au

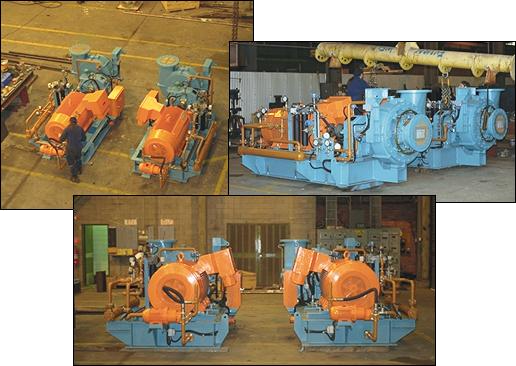

Skid Mounted Systems: Revolutionising Petrochemical Processing

August 26, 2024

Discover how Skid Mounted Systems are revolutionising petrochemical processing. Enhance efficiency and provide flexible solutions for modern industrial needs.

Skid Mounted Systems are transforming petrochemical processing, offering a multitude of benefits that streamline operations and enhance efficiency. These modular units integrate various mechanical, electrical, and instrumentation components into a single, transportable structure, making them ideal for industries that require flexibility and rapid deployment.

The Rise of Skid Mounted Systems in Petrochemical Processing

The petrochemical industry has traditionally relied on large, fixed plant installations. However, the need for more agile and cost-effective solutions has led to a surge in the adoption of skid mounted systems. These modular units offer several advantages that make them particularly well-suited to the evolving needs of the petrochemical sector:

• Flexibility and Scalability: Skid mounted systems allow for easy expansion or modification of existing plants. As production needs change, new modules can be added or removed without significant disruption to ongoing operations. This flexibility is particularly valuable in the fast-paced petrochemical industry, where market demands can shift rapidly.

• Reduced Installation Time and Costs: One of the most significant benefits of skid mounted systems is the dramatic reduction in on-site installation time. Since the modules are pre-assembled and tested in a controlled factory environment, they can be quickly installed and commissioned at the plant site. This not only reduces labour costs but also minimises disruption to existing operations.

• Quality Control and Safety: Factory assembly of skid mounted systems allow for stringent quality control measures and thorough testing before deployment. This results in higher quality, more reliable systems that meet or exceed industry standards. Additionally, the controlled environment of a factory allows for better implementation of safety measures during the construction process.

• Portability and Reusability: Skid mounted systems can be easily relocated if needed, offering a level of portability that traditional fixed plants can't match. This is particularly advantageous for temporary or mobile operations, or when production needs to be shifted to a different location.

• Customisation and Standardisation: While skid mounted systems can be highly customised to meet specific process requirements, they also allow for the standardisation of common modules. This standardisation can lead to reduced engineering costs and faster delivery times for future projects.

Applications of Skid Mounted Systems in Petrochemical Processing

Skid mounted systems are versatile and can be applied to various processes within the petrochemical industry. Some common applications include:

• Separation and filtration units

• Heat exchangers and cooling systems

• Chemical injection and dosing systems

• Fuel gas conditioning systems

• Water treatment and waste management units

• Analyser systems and sampling stations

• Compression and pumping stations

Fusion-Weld Engineering is an expert in designing and fabricating skid mounted systems that allow us to offer our clients innovative solutions that meet the complex demands of modern petrochemical processing.

Whether you're looking to upgrade existing facilities or embark on new projects, consider the transformative potential of skid mounted systems. They're not just a trend – they're the future of petrochemical processing.

Contact Details

Fusion - Weld Engineering Pty Ltd

ABN 98 068 987619

1865 Frankston Flinders Road,

Hastings, VIC 3915

Ph: (03) 5909 8218

Optimized by NetwizardSEO.com.au

Recent Posts

- Large-Scale Pressure Vessel Fabrication: Handling Vessels Up to 200 Metric Tons

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- Pressure Vessel Fabrication: Engineering Efficiency for 2026 Petrochemical Projects

- Heat Exchanger Maintenance in Melbourne: Minimising Risk in Power Generation Facilities

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- AS1210 vs ASME VIII Pressure Vessel Code: Key Differences for Australian Projects

- Mitigating Hydrogen-Induced Cracking in Pressure Vessels: Engineering and Material Strategies

- Storage Tank Solutions Australia: Field-Erected, Prefabricated & Self-Bunded Explained

- Reducing Environmental Risks: Self-Bunded Tanks in Australian Oil & Gas Operations

- Precision in Production: How Pressure Vessels Are Manufactured for Industrial Safety

Posts 2026

- Large-Scale Pressure Vessel Fabrication: Handling Vessels Up to 200 Metric Tons

- Process Skid Fabrication Melbourne: Modular Plant Solutions for 2026 Projects

- Pressure Vessel Inspection: Ensuring Peak Efficiency in 2026 Oil & Gas Operations

- View all articles…

Posts 2025

- Compressed Hydrogen Storage Vessels: Material Selection, Design & Australian Standards

- Welding QA/QC in Oil & Gas Pressure Vessel Fabrication – Ensuring Code Compliance

- View all articles…

Posts 2024

- Large Process Vessels: Optimising the Design for Maximum Efficiency [2025]

- Pressure Equipment Management System Installation: Detect Equipment Faults Early

- View all articles…

Posts 2023

- Pressure Piping System Inspection: A Gift of Safety for the Holidays

- Deaerator Inspections by Fusion-Weld Engineering and How They Reduce System Downtime

- View all articles…

Posts 2022

- How Fusion Weld Keeps Up With AS-NZS ISO 9001:2008 Standard

- Boiler Equipment Safety Inspection During the Summer Season

- View all articles…

Posts 2021

- Avoid These Factors and Practices that Contribute to Sealing Damage in Pressure Vessels

- Do's And Don'ts Of Industrial Boiler Inspection And Maintenance From Fusion-Weld

- View all articles…

Posts 2020

- What are the Risks and Hazards Involved in Pressure Vessel Equipment?

- How to Know if Your Pressure Equipment Needs Repair or Replacement?

- View all articles…

Posts 2019

- Factors that Contribute to Pressure Vessel Failure

- Pressure Vessel Regulations in Australia: What are the Mandatory Requirements?

- View all articles…

Posts 2018

- Pros and Cons of Spherical vs. Cylindrical Pressure Vessels

- What are the Different Hazard Levels in Pressure Vessels?

- View all articles…

Posts 2017

- Transportable Pressure Vessels: The Importance of Inspection and Safety Checks

- Fracture Mechanics and Stress Analysis of Cracks in Pressure Vessels

- View all articles…

Posts 2016

Posts 2015

- What Are Deaerators & Feedwater Vessels?

- Precautions and Safety for Compressed Air Receiver Vessels

- View all articles…

Posts 2014

- Demonstrating In-process Inspection Procedures

- Static Grounding Practices and Standards

- View all articles…